We design and build resistance welding systems for companies ranging from the automotive industry to metal furniture manufacturers, from wire products manufacturers to providers of complex components.

Your production process can be simpler, faster, safer and more flexible. Our solutions prove it — welding every day for nearly 40 years.

Discover how welding can become your competitive advantage.

We design custom systems for any major resistance welding application: spot welding, projection welding and wire or rod welding.

Fixed manual welding machines with different configurations.

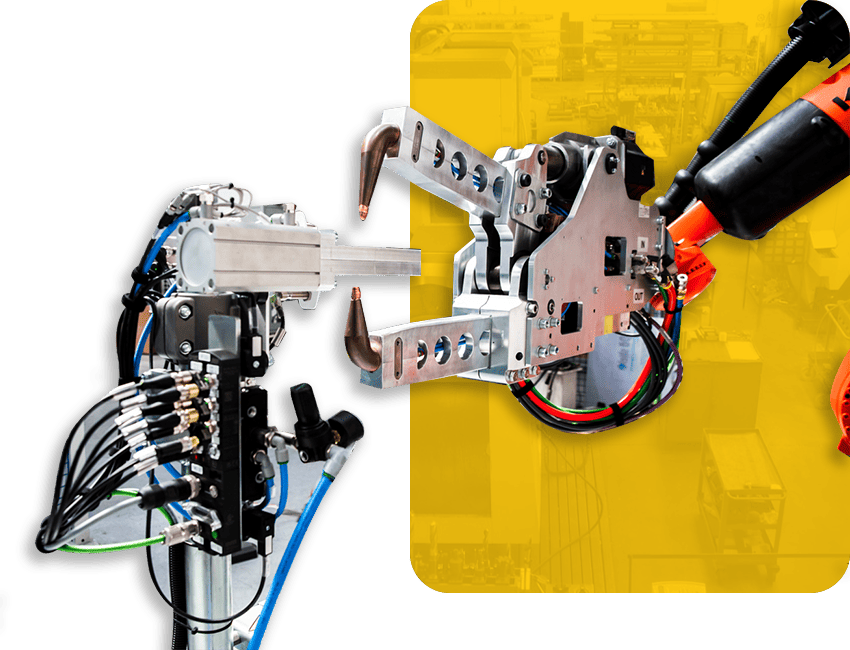

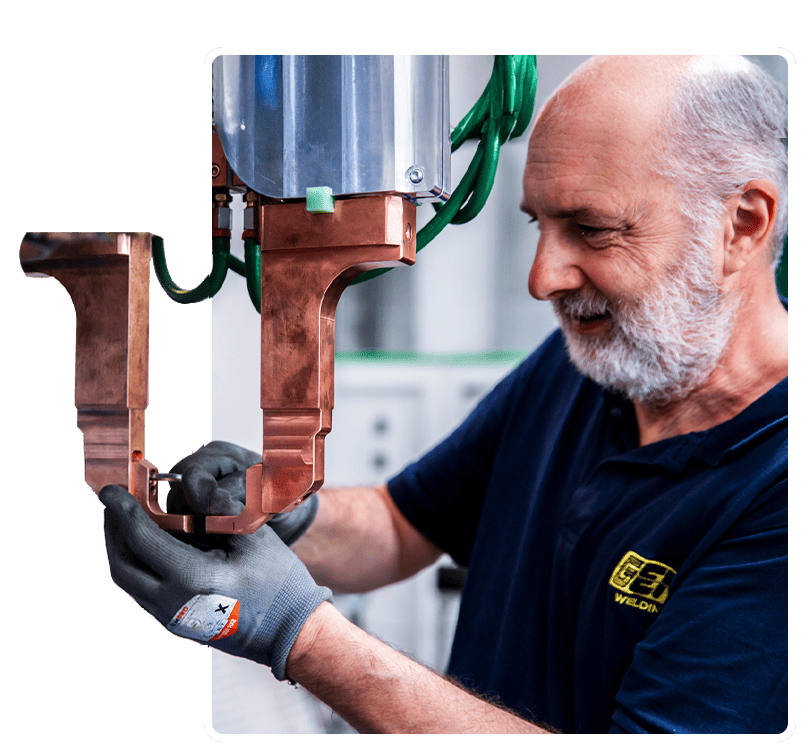

A complete range of components for automatic and robotic systems, including welding guns, multi-head modules, pneumatic cylinders, automatic feeders, and electrode dressing systems. Solutions designed to optimize every stage of the production process.

Every GEM system is created at our Robassomero facility, where we design, build, and test every solution. From robotic cells to individual components, we oversee every stage with artisanal care and industrial technology.

This approach allows us to produce each machine in-house, guaranteeing reliability, total control and tailor-made solutions for every production need.