Fixed, Multiple and Equipped Machines

Fixed, Multiple and Equipped Machines

Fixed & Equipped

Fixed spot welder

F20 High-Speed Welder

Elevato grado di produttività: ogni ciclo macchina vengono prodotti nr.2 pezzi. Elevata versatilità con slitte motorizzate da 1 a 3 assi.

Fixed Spot Welder

F09 with lance and load protection

Manual component loading and automatic nut/screw loading.

Loading area protection with photocells.

Option for automatic unloading and red box.

Fixed Spot Welder

F09 with lance and load protection

Manual component loading and automatic nut/screw loading.

Loading area protected by photocells.

Before unloading, the nut welding is checked 100% with a screwdriver and torque limiter.

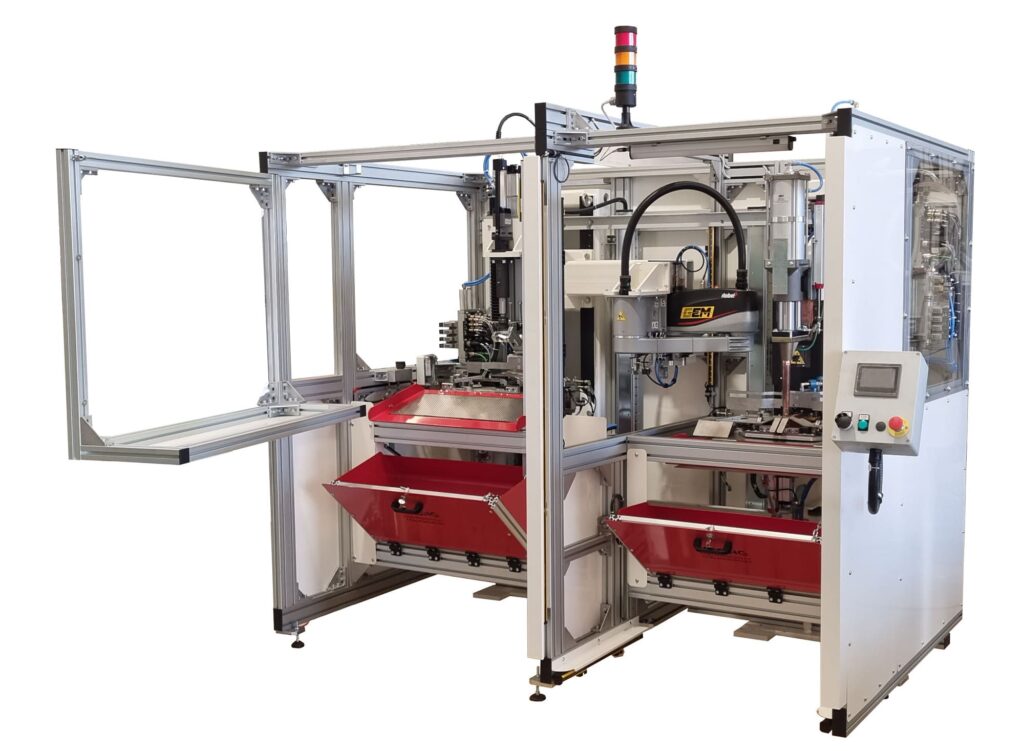

Fixed Spot Welder

F20 High-Speed Welder

High productivity: 2 pieces are produced per machine cycle. High versatility with 1- to 3-axis motorized slides.

Modular structure with AC or MFDC welding generators.

Automatic nut/screw loaders that ensure the presence and correct positioning on the piece to be assembled.

Complete with fence with photocells and automatic unloading with waste selection.

Fixed manual spot welders for

spot or projection welding

They can be supplied with reference masks and any accessories.

Multiple

Multiple spot welder

for solar panels

Modular machine with the ability to increase or decrease welding modules depending on the size of the panels being assembled.

Robotic control.

Multiple welding machine

for armored doors

Multiple spot welder for assembling armored doors, panels, and fire doors with a robotic system and parametric programs.

Multiple spot welder

for armored or fire door frames

Modular version for different types of sizes and models.

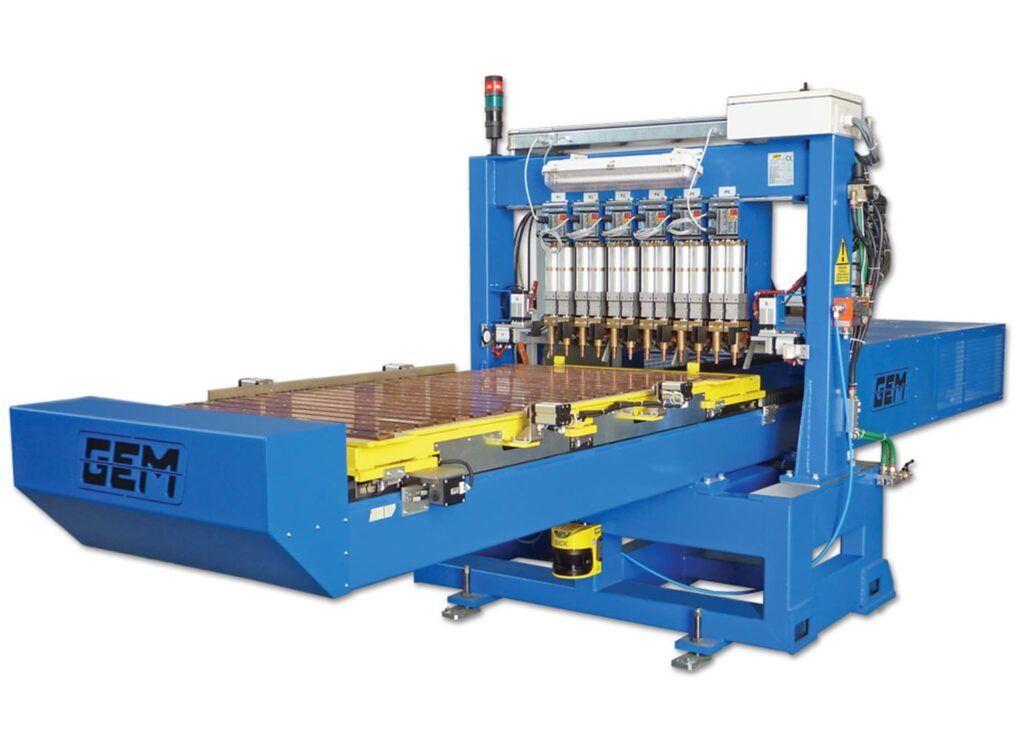

Multiple spot welder

Gantry type for welding grids onto tubular steel

Designed for welding mesh onto tubular steel.

Panel loading and movement is manual, using a programmable rear stop.