Marta System

The heart of our automated welding technology

The Marta System is our flagship cartesian robotic solution, designed to deliver precision, efficiency, and versatility in resistance welding applications.

Unlike traditional anthropomorphic robots, Marta operates on interpolated X-Y-Z axes, ensuring a limited use of space, quick retooling, and intuitive operations.

The system is based on a modular and flexible concept: it can be configured and customized to suit different production needs, whether for spot welding, projection welding of nuts and bolts, or working with wire and rod components. Available in different configurations with pneumatic or electric guns, and AC or MF welding systems.

Each Marta System is engineered to meet specific requirements, with the ability to weld multiple similar or compatible products within the same machine—making it the ideal solution for manufacturers handling small batches of diverse components.

Below you’ll find some of the configurations we’ve developed over the years.

If you don’t see the solution that fits your needs, contact us: we’ll be glad to design the right Marta System for you.

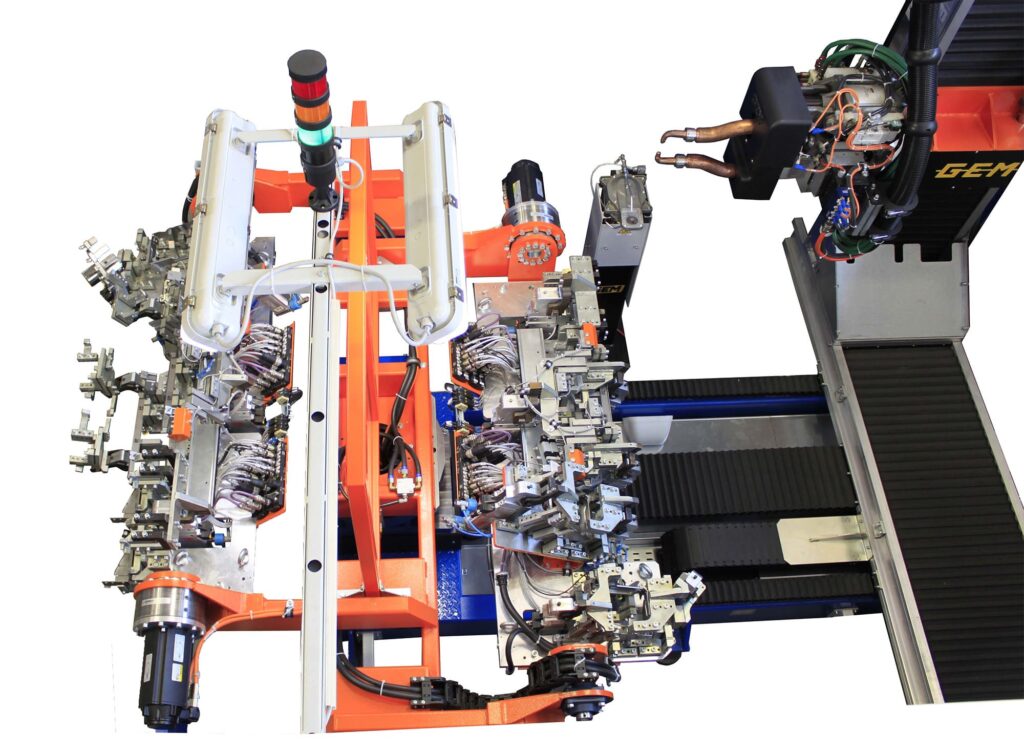

Spotting

Marta System

Single clamp

Welding module with fulcrum clamp (AC/MF) and rotary table with lathe positioner for workpiece orientation.

Marta System

Double X clamp

Welding module with double fulcrum clamp (AC/MF) and rotary table with lathe positioner.

Allows simultaneous work on two components to halve cycle time.

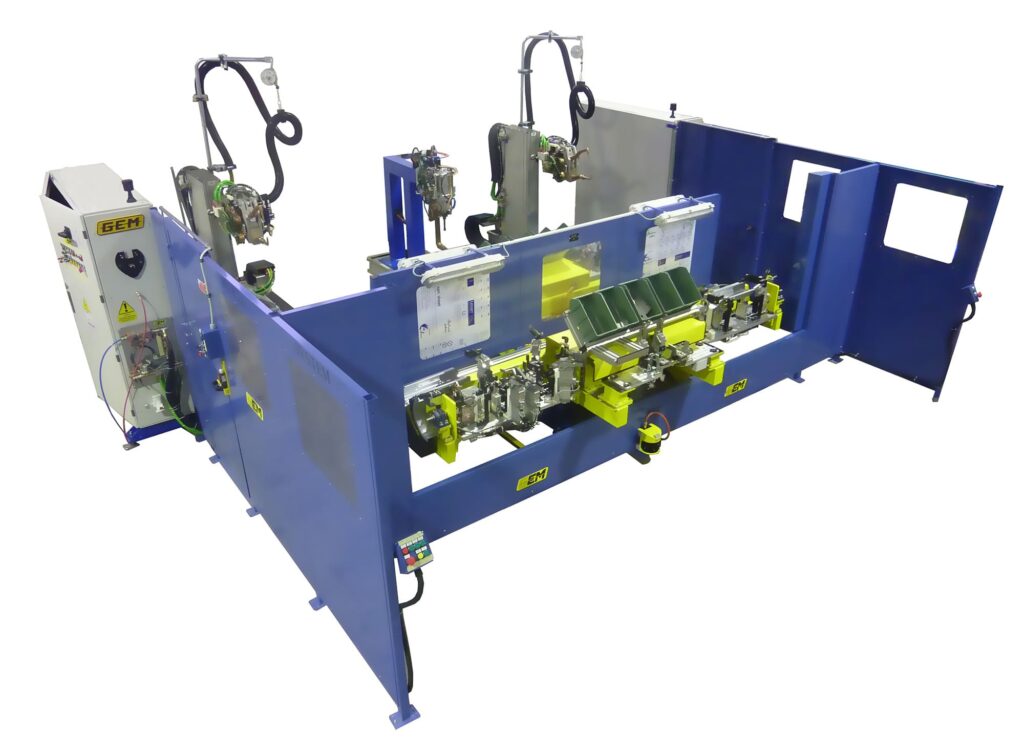

Marta System

Large “C” clamp

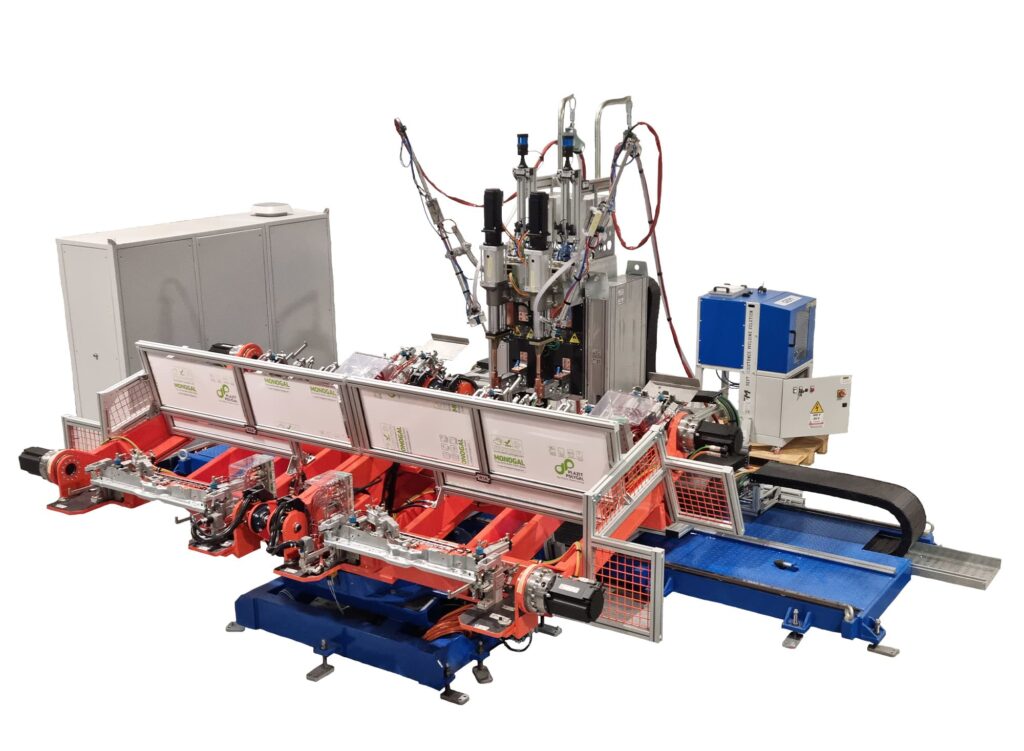

Projection

Marta System

Proiezione 13AX: double module double lathe version

Rotary table with double lathe.

Allows you to work on two components simultaneously to halve cycle time, or perform two different operations on the two stations.

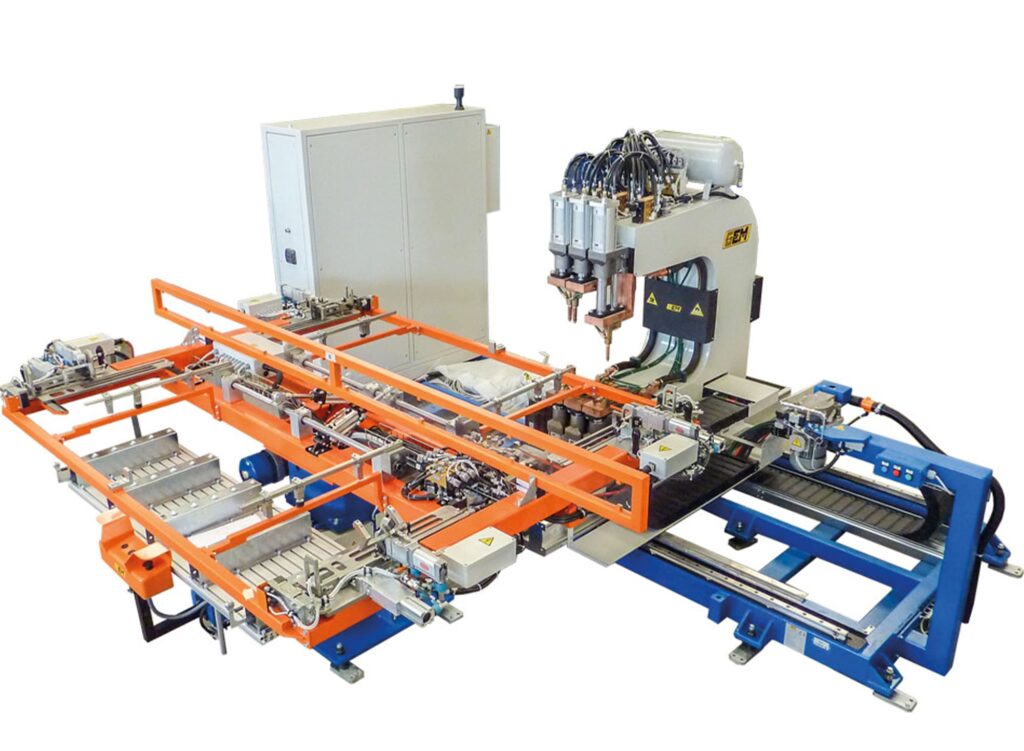

Tondino

Marta System

8 AX parallel gripper

Marta System

large “C” clamp for rebar

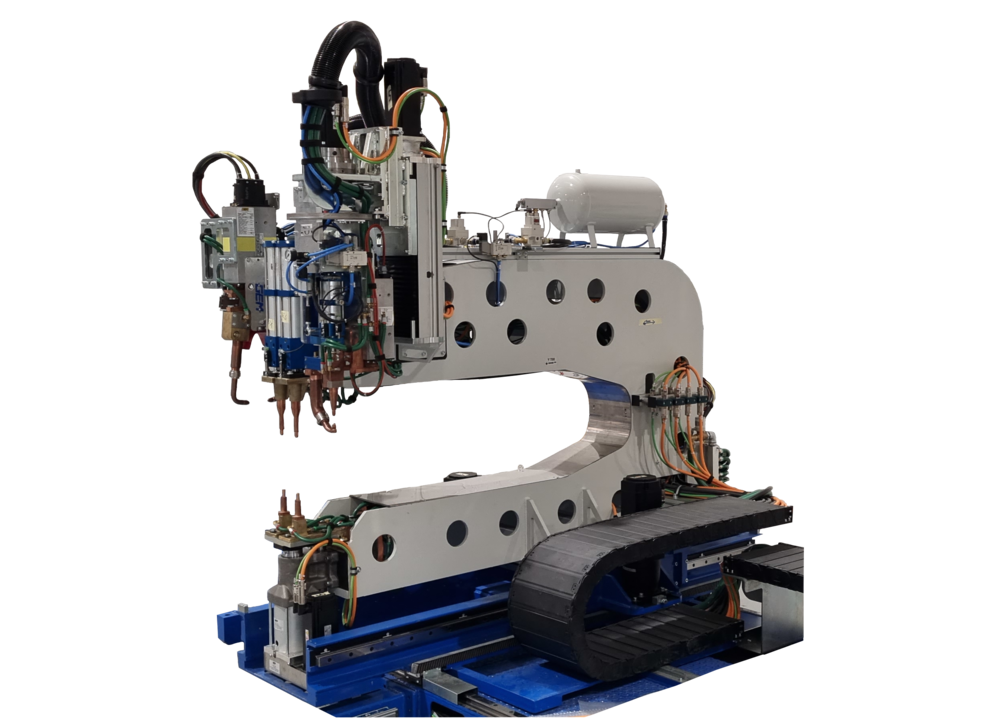

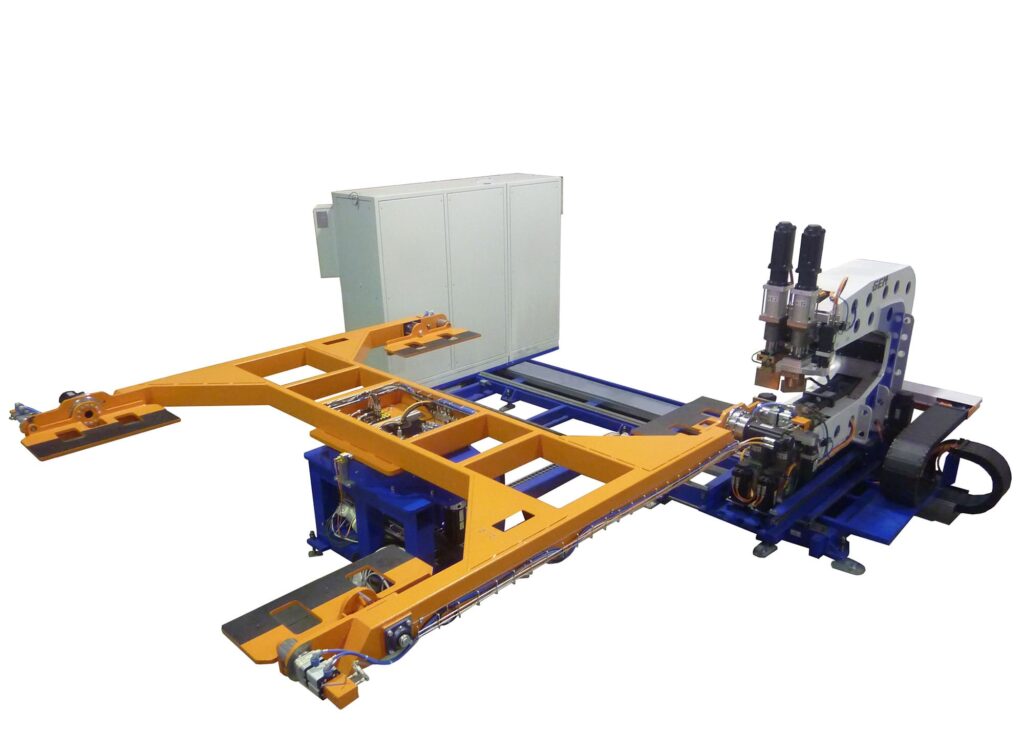

Hybrids

15AX Hybrid – 2 nut welding modules + X-gripper module